Acrylic laser cutters are among the most utile appliances in the personalization industry. Acrylic is a strong and versatile material that can be used for anything from signage to display cases. Acrylic awards can be laser engraved, and you can even create your own awards with an acrylic laser cutter. They are easily one of the most beneficial tools for working with acrylic, as they have many major advantages over traditional tools.

Traditional Acrylic Cutting Hurdles

Let’s first discuss the cons when working with acrylic with traditional tools. Using a plastic scoring blade limits you to straight cuts and using a jigsaw or router can break the acrylic when working on more intricate cuts. Furthermore, no matter what method you use, traditional tools will always leave your acrylic with a rough frosted edge that you have to flame polish to achieve a finished look. This process is not only time-consuming, but you risk damaging the acrylic.

Advantages of Acrylic Laser Cutters

Now, we’ll showcase all of the pros of working with a laser cutter for acrylic. Lasers cutters make cutting acrylic a breeze and streamline your processes. A laser cutter for acrylic makes it possible to quickly change designs, as well as produce the same design over and over with perfect results every time. Laser cutters are also easy to use, as they function as a printer. There is also less margin for error; a laser cutter is computer-based and works off of the X and Y-axis.

How to use your AP Lazer to cut an acrylic cell phone holder

Many acrylic projects can be completed start to finish with only a laser machine, completing all of your cutting and engraving in one step with complete automation. More importantly, an acrylic laser cutter is able to achieve extremely intricate cuts with little to no risk of the acrylic breaking. And, when cut with a laser, there is no need to flame polish the edges of your piece because this happens automatically as it’s being cut by the laser.

Get our FREE Business Growth Guide

What is the Best Laser for Cutting Acrylic?

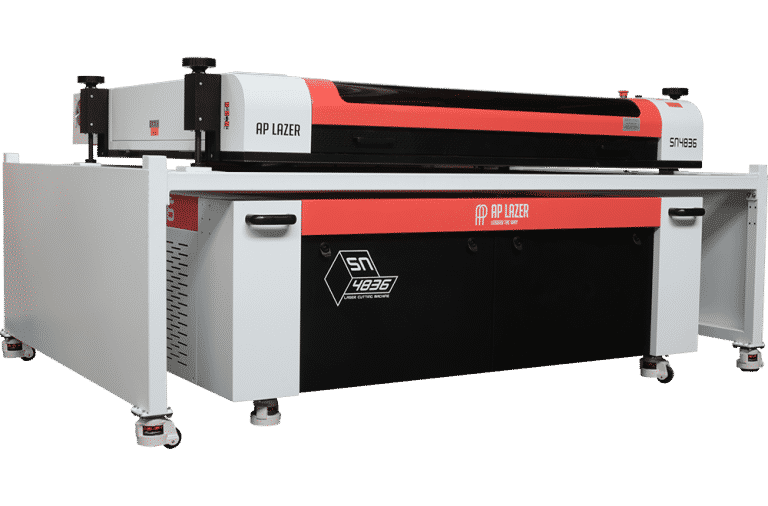

Obviously, an AP Lazer! You might be thinking “That’s great but what does an AP Lazer offer that other laser machines don’t?”. The answer to that lies in the patented open-architecture design of our all-purpose laser cutter systems. Large sheets of acrylic can be heavy, unwieldy, and nearly impossible to work on with traditional laser machines, however with AP Lazer’s open architecture, working with sheets of acrylic of any size is a breeze and you’ll even be able to cut and size your sheets to any size necessary, up to ¾” thick.

With an AP Lazer, you can also etch and engrave your acrylic designs using the variable speed and power settings, bringing an entirely new dimension to your acrylic work. With an acrylic laser cutter that goes far beyond the limited function and capacity of traditional “box style” laser machines, you can create products that exceed the competition and are limited only by creativity.

Our patented design is ideal for users seeking solutions for signage applications. And remember, when using an acrylic laser cutter, there’s no buffing or flame polishing edges, no ruining material due to an accidental slip of the hand, and unlike other machines, no pass-through system is necessary. This makes the AP Lazer the one machine for all applications and users.

Interested in trying an acrylic project with an AP Lazer?

Contact us today to get started!

Ready to grow your business?

Download our free guide: The Ultimate Business Growth With AP Laser.

I am looking for comparisons of machines on the market.

Capabilities, costs of equipment!, software accessories, erc.

Hi there! You can find info on pricing, features, and model comparisons here https://staging1.aplazer.com/laser-machine-pricing-comparison/ All of our machines come in a complete turnkey package, 3-year warranty, one on one training, and a lifetime of tech support. If you’d like to provide a good email for you, I’m happy to get you connected with a laser expert for further assistance!