Laser Machines for Engraving and Etching Glass

Marking and Engravingfor Glass Materials

By integrating AP Lazer machines into your business and production lines, you open up new revenue opportunities. Our CNC laser machines are perfect for engraving and etching glass products. Etched glass can create the most amazing visual effects.

Glass products are extremely diverse and come in all shapes and sizes. Our laser machines can etch and engrave designs on everything from glass tumblers to vehicle windshields. Our CO2 laser machines for glass etching and engraving are extremely accurate and reduce errors, minimize wastage, and prevent delays in production.

New Income StreamsDownload our Business Growth Guide

Too often, businesses come up with clever ideas but get discouraged because it’s too hard to get those ideas off the ground. AP Lazer hopes to break this pattern by providing glass product manufacturers with the technology and tools to innovate.

Here is an e-book with tips on how to generate new income streams for your business. Download this ebook today for more pointers on innovating with glass.

Modernize Productionof glass products

Considering the vast array of uses for glass products, it has become one of the most sourced materials for a variety of manufacturers. And with glass products gaining popularity with consumers, it’s become a favorite material for artisans, manufacturers, and custom designers alike.

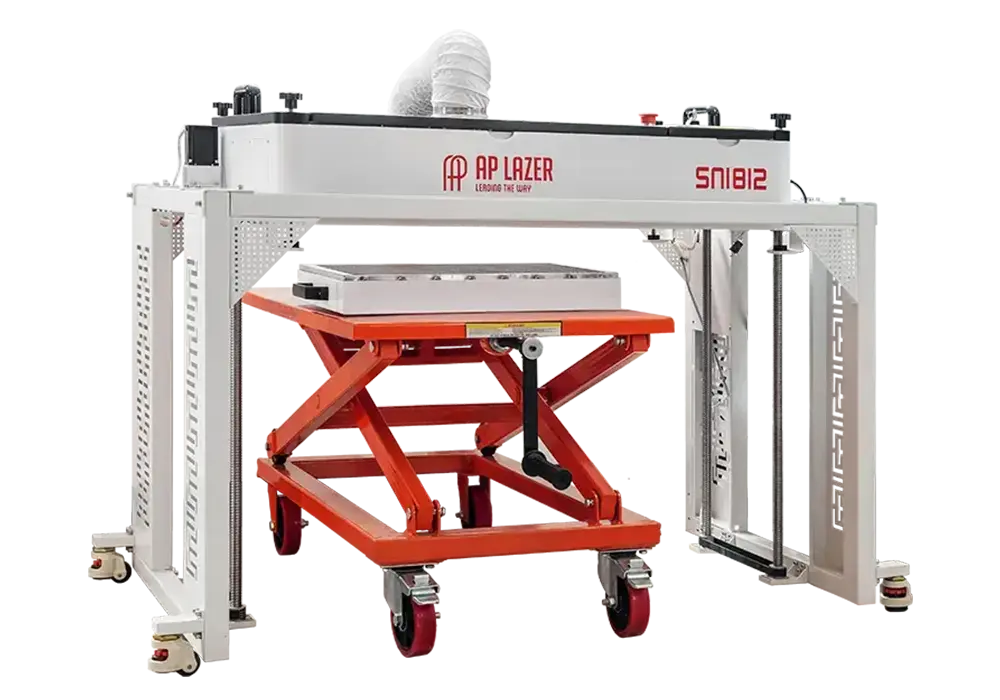

If your business works with glass materials or products, you’ll have lots to gain from AP Lazer’s CNC laser machine for glass etching and engraving. Our machines boast an open-architecture set-up, which allows you to update functions and personalize its features to specifically meet your production needs. Our larger models also have a versatile design: you can remove the laser top, which will give you more space to etch and engrave glass objects that are bigger or wider than the provided workspace.

Technology and Sciencelaser etching and engraving glass

Our glass laser engravers are highly customizable, as a result of our market research. Because that our technology can set the precise dimensions, shapes, engravings, and markings they want to add to glass materials. And as it is computer-aided, the laser machine can continue operating without constant human supervision.

In a nutshell, AP Lazer machines can help improve many aspects of your production line, such as speed, wastage, and quality control. Small or big, businesses that rely on laser engravers for glass products can trust the AP Lazer brand.

Application Ideas

- Car windows

- Tiles

- Mirrors

- Wine glasses

- Beer growlers

- Liquor bottles

- Fermentation Bottles

The Process of GlassLaser Engraving and etching

Laser engraving actually removes a portion of the material by vaporizing it and thereby leaving a small cavity that reveals a design. This can be observed with both sight and by touching the material. Engraving depths vary slightly and average between 0.02″ and 0.125″ depending on the hardness of the material.

Laser etching, on the other hand, does not cut into the glass material in the same manner as engraving. This process only removes the very most outer layer for this effect.

How It Works

When laser etching glass, the end result is often a look of quality and class. Laser etching glass or crystal leaves a frosty mark on the surface that stands out, yet is smooth to the touch.

Two Types of Glass Processes

- Engraving Glass- The physical process of vaporizing a shallow layer of glass material thereby leaving a cavity or void which showcases the design.

- Etching Glass – The physical process of removing the outermost top layer of glass by removing around 0.001″ giving the glass a frosty look that slightly opaque.