Laser Machines for Leather Engraving

Laser Engraving Machine for Leather products

Use the AP Lazer technology to add a premium product and service to your custom engraving business. Our CNC laser engraving machines are configurable to engrave leather surfaces and cut through leather materials — cleanly, quickly, and precisely.

For the price of one machine, you can engrave, cut, etch, and mark on premium leather. You’ll be able to sell products for which your customers will also be willing to pay a premium price.

Generate New Revenue Download our Business Growth Guide

What if there was an idea you haven’t thought of yet? It might be the next big thing that will drive profits to your business.

Download this guide and learn how to make the most of your AP Lazer to increase your business’ earnings.

Create Leather Productswith AP Lazer Technology

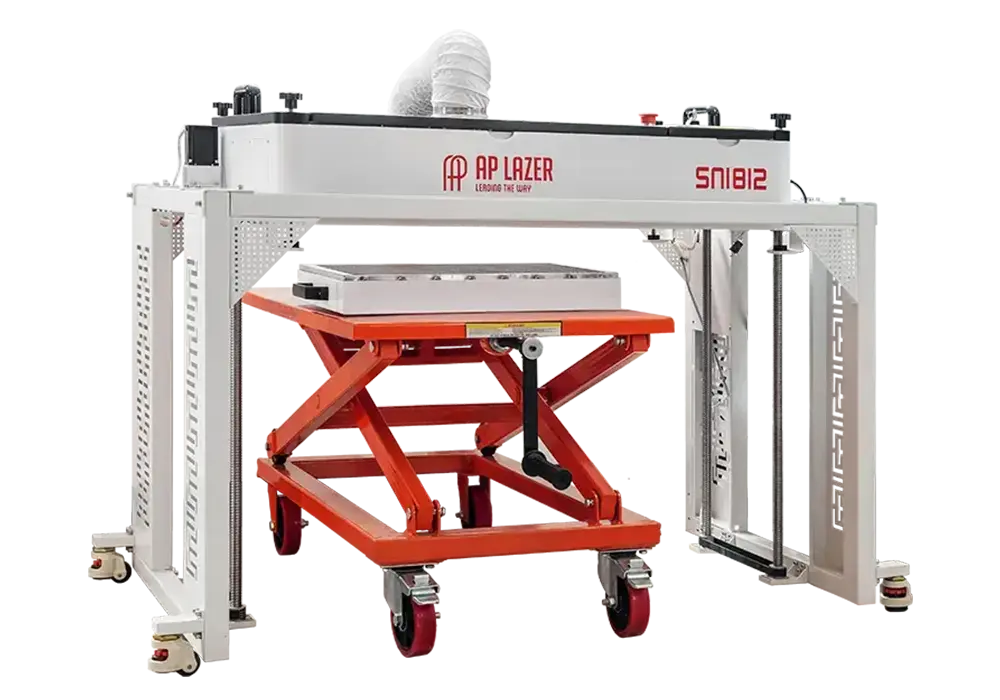

We offer multiple laser cutting machines, each of which is designed to accommodate various production output demands and functions. Our bigger and more robust models, for example, are designed to make room for large items or leather sheets that require a 48 x 36 in workspace. Similarly, we have a smaller laser cutting machine with a workspace of 18 x 12 in.

How does CNC laser machining work? The machine generates a laser by sending an electric current through a narrow tube that contains a gas mixture of CO2, hydrogen, helium, and nitrogen gases. This produces a laser beam of such intense heat, it can vaporize materials that pass through it. Our machines use reflective mirrors to direct guide the beam through the cutting workspace. The entire contraption is controlled by computer software. This is how users can configure dimensions when cutting leather or program designs for etchings and markings.

Types of Leather You Can Use with AP Lazer

Leather is a fun material to engrave and cut because it has so many functional uses and takes to the laser so well without needing additional materials to show off the engravings. With a reputation for our powerful and impressive production performance, AP Lazer cutting and engraving machines can work on all types of leather.

Want to see more? Check out this video showing how to cut and engrave leather.

How it Works

Easy to both cut and engrave, leather is a high-end material and can be used to create custom clothing and shoes. With many colors of leather available, the possibilities are endless!

- Full-grain premium leather

- Top-grain leather

- Corrected-grain leather

(a.k.a. genuine & embossed leather) - Bonded leather

- Suede leather (both split and nubuck)

- Synthetic leather

- Fiber leather

(a.k.a. reconstituted or recycled leather)

Do More with Leather through AP Lazer

Streamlining your production of leather products through technology doesn’t diminish the quality of the materials you’re using or the genius of the design you’re going to make. With our high-performance machines, you can set your business up for success.

CNC-guided laser cutting is a cost- and time-effective method for creating premium leather products. It reduces the risk of errors, which in turn could result in wasted materials, time, and other resources. CNC laser cutters can reproduce the leather materials you need for assembly, while the engraving function allows you to replicate designs for products that are in-demand. Finally, our CNC technology also allows you to create one-in-the-world, personalized designs if requested by your customers.

Whether you want to make a name as a mass producer of quality leather products or promote your company as artisanal with your attention to detail and high level of customization, you can accomplish your goal with AP Lazer.

Application Ideas

- Horse saddles

- Hat patches

- Purses and wallets

- Jewelry

- Bound journals

- Key chains and bracelets

Shop high-performance laser cutting machines

AP Lazer boasts over 50 years of combined laser experience. We help businesses grow and diversify through cutting-edge systems and unique personalization services.

Our machines can transform ordinary products into something special. Browse our technologies now or contact our team for product advice.