- But What Size Laser Machine Should You Purchase?

- 1. How Easy is the Laser to Use?

- 2. What File Types does the Laser Accept?

- 3. What Type of Software Comes with the Laser?

- 4. What Can a Laser Do?

- 5. Cutting with a Laser

- 6. Complete Large Projects

- 7. Create More Product in Less Time With a Larger Laser Machine

- 8. Open Architecture Open Doors to a Plethora of Additional Market Opportunities

- 9. All Machines Come With Training

- 10. Explore Other Possibilities with Our Galvo Fiber Laser Machines

What products will I cut/engrave with it? Where will I put it? How will I pay for it? What size laser machine should I purchase?

These are a few questions that most new laser machine buyers will find themselves asking at some point or another during their research.

In this article, our goal is to help you determine what size AP Lazer machine you should purchase. We have a full lineup of CO2 laser systems, and we’re sure there is one that will fit your exact needs. From our entry-level, SN1812LR and SN2616LR to the open bottom style SN4836LR, all AP Lazers feature a patented open-architecture design that you won’t find with any other laser machine.

But What Size Laser Machine Should You Purchase?

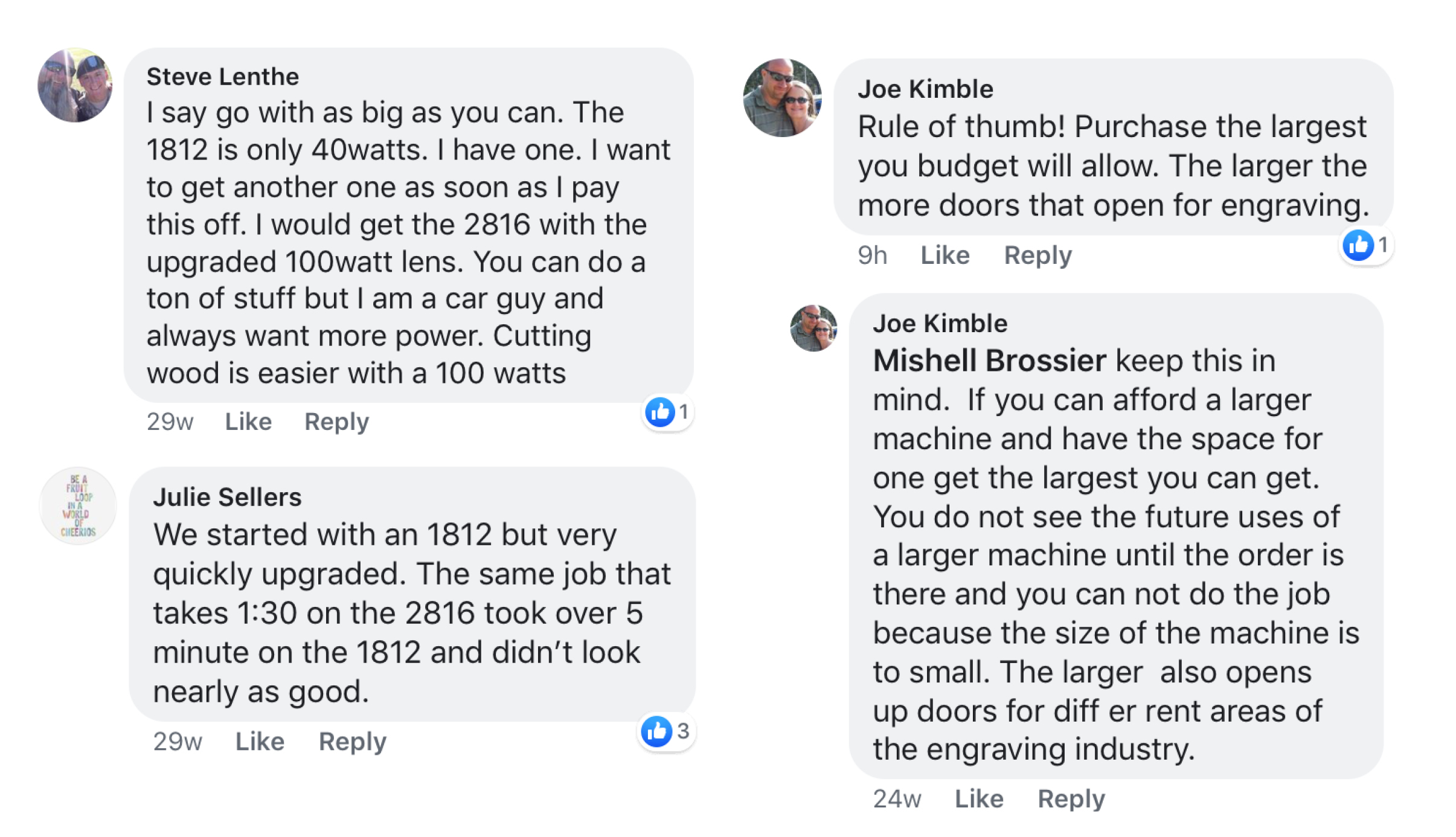

(This question, specifically in regards to the hobby SN1812LR laser machine, gets asked multiple times a week in our Before You Buy Facebook Group.)

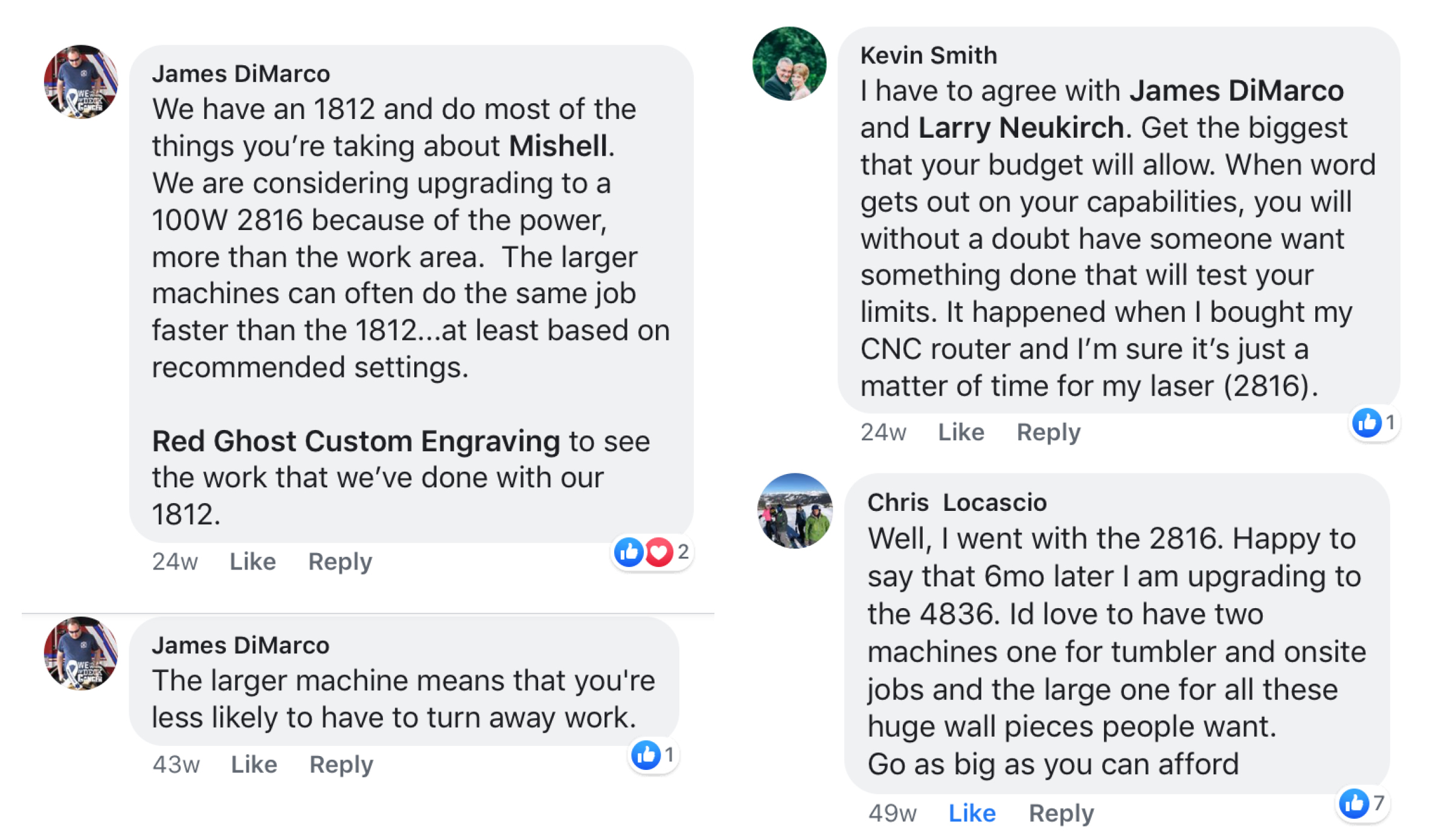

With 5 different models, the choice may be difficult. After speaking with a handful of current machine owners who have experience running multiple-size machines, the verdict is in: “Purchase the largest AP Lazer machine that you can afford.” However, if the budget doesn’t permit a larger machine – no worries! We have a great trade-in trade-up program where you can upgrade to a larger machine when you are ready.

As a new business just starting out, or an established business looking to diversify with priceless products, you may be wondering… “Why?”

1. How Easy is the Laser to Use?

The lasers themselves are very easy to use! Most people find that the learning curve is mostly the computer side of things if they have never dabbled in graphic design. But rest assured, we offer one-on-one training with each customer, 24/7 phone support, AP Lazer University step-by-step video tutorials, as well as our Facebook User Group! Our User Group is amazing and is filled with new and experienced customers who will go out of their way to help you if needed.

We have many successful customers from all walks of life – some with little to no laser or computer experience at all! A great example is Bonnie Gilbert from Port Huron, MI. She and her husband were retiring and decided to get into the laser market to get some supplemental income. With little computer/laser experience, she has been able to excel with her startup business. Check out her story here.

Bonnie says, “I always suggest using Lightburn Laser Software to start out with, as it is easy to use and great for beginners! I can typically have something designed, (such as a cutting board or tumbler) within 5 minutes.”

Here’s a great video showing the step-by-step process of designing something in Lightburn:

2. What File Types does the Laser Accept?

The laser machine can accept many different file types such as DXF, PNG, PDF, BMP, SVG, AI, and more. Most images you may want to use may come from the internet, (such as Google Images or even a file that a customer may send you). Most vector images, (or images mostly made of simple lines and curves) are easily traceable within our software provided and can be easily edited. Photographs can also be processed with the software provided.

3. What Type of Software Comes with the Laser?

Each of our laser machine models comes with a laptop computer and the software needed to design files and run the laser.

Our entry-level lasers, the SN1812LR, and SN2616LR come with Lightburn laser software.

NOTE: One thing we suggest to add on with these models is the photo package – which includes Corel Draw and Photograv. It is an $800 add-on, but you do get an additional 4 hours of virtual training when you add the extra software package on, (a total of 8 hours). These 2 additional softwares are helpful if you want to get into more advanced graphic images such as designing your own designs from scratch, and processing /editing photographs.

Our larger models, the SN2816LR, SN4024LR and SN4836LR come with RD works laser software, (virtually the same as Lightburn), Corel Draw the full suite, and Photograv photo-processing software.

4. What Can a Laser Do?

Basically, CO2 laser machines can engrave on almost anything. From 10 ft long monuments to pumpkin pies, laser machines are extremely versatile! You can also cut some things such as wood, acrylic sheets, fabric, leather, MDF, and more! Note: you can not cut metal with the laser machines, but you can “engrave” it!

Below is a list of the most typical items that you can engrave and/or cut with the laser machine.

5. Cutting with a Laser

The thickness of how much you cut depends on the wattage (or power) of the laser machine you get. Below is a quick overview of our different models and the approx thickness of materials you can cut.

Remember, the thickness of some materials such as wood depends on the type of wood you are cutting. For example, plywood or bamboo is a little denser and is harder to cut than, let’s say a soft pine. Typically, I say that on our 100-watt machines you can cut about 1/2″ of plywood, but 3/4″ of softer woods.

Also, acrylic cuts very nicely with the laser machines! We have even cut 1 full inch thick of acrylic on a 100-watt machine. It leaves a smooth, “flame polished edge” when cut with a laser – great for sign making!

SN1812+ 30-watt machine: Approx. 1/8″

SN2616 60-watt machine: Approx. 1/4″ – 1/2″

SN2816 90-watt machine: Approx. 1/2″ -3/4″

SN4024 100-watt machine: 3/4″ (even 1 full inch of acrylic)

SN4836 100-watt machine: Up to 3/4″ (even 1 full inch of acrylic)

6. Complete Large Projects

Do you have something you need to engrave that is too big for your laser? Rest assured, AP Lazer knows the way!

Image stitching or photo stitching is the process of combining multiple photographic images with overlapping fields of view to produce a segmented panorama or high-resolution image. In other terms, it is a way to break up an image into segments so that you can engrave objects larger than the engraving area of your laser!

The process can be slightly challenging, but it is definitely not impossible! We see customers doing it all the time on our Facebook User Group. They have done image stitching on anything from bar tops, large doors, monuments, and more!

There are a few ways to do it. Most people will set up the file, (telling the laser software to stop at a certain point), and engrave the first section. Next, you can either reposition the laser or the object and get it lined up properly. By laying down a strip of masking tape, (or other mediums) you can lightly engrave into the object as a test strip, (to make sure you have everything lined up properly. Once you have it lined up perfectly, you push start and there you have it!

7. Create More Product in Less Time With a Larger Laser Machine

7. Create More Product in Less Time With a Larger Laser Machine

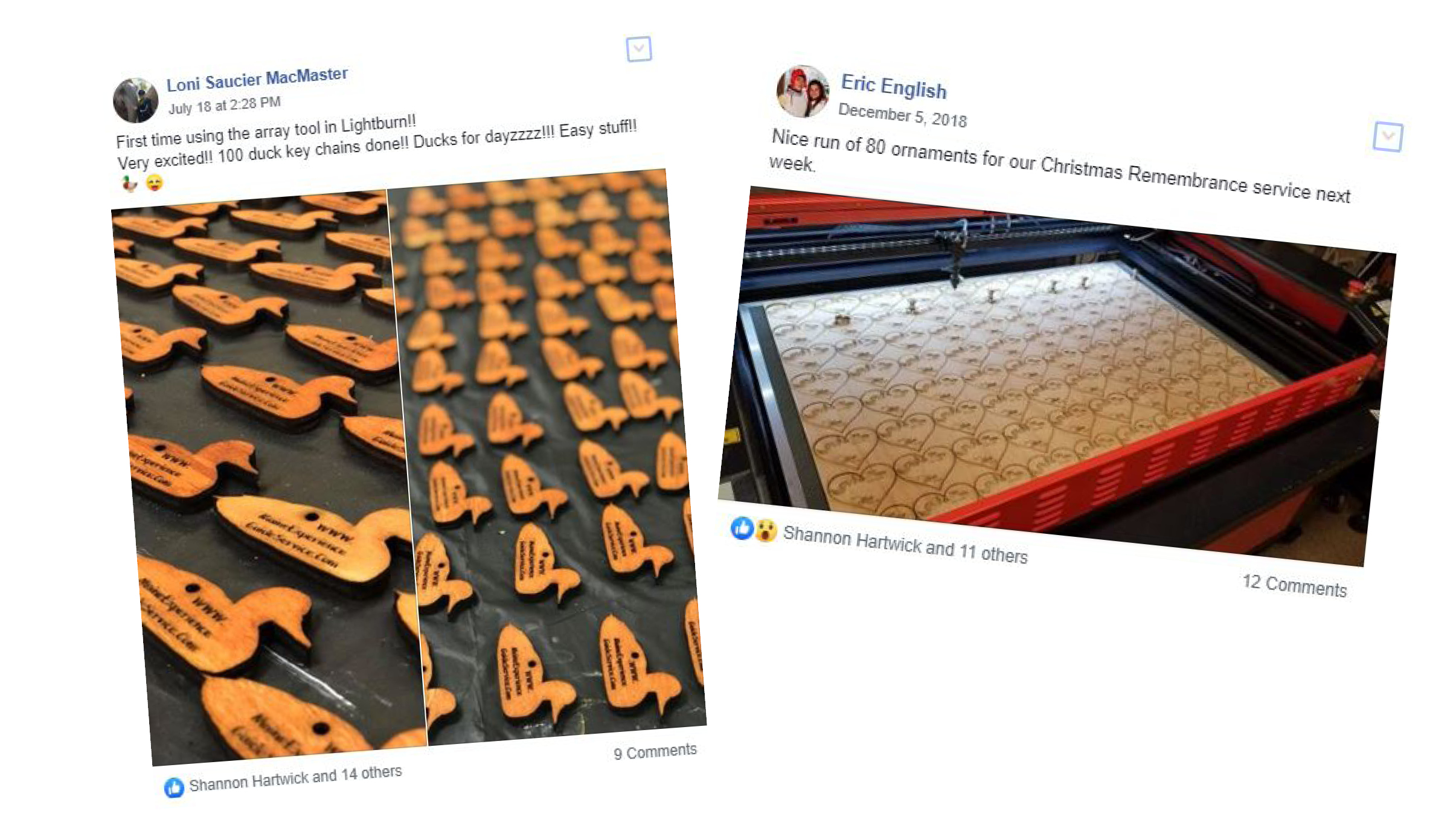

Have you ever heard of the term “array”? In laser talk, an array makes it possible to cut hundreds of the same exact files in one run. The machine software can easily create a file with systematically placed rows and columns so you can produce exact cutouts over and over again. If cutting 216 one-inch circles in a single run on the SN1812+ sounds like a lot, imagine being able to cut 1,728 on the SN4836. That’s EIGHT times the amount!

8. Open Architecture Open Doors to a Plethora of Additional Market Opportunities

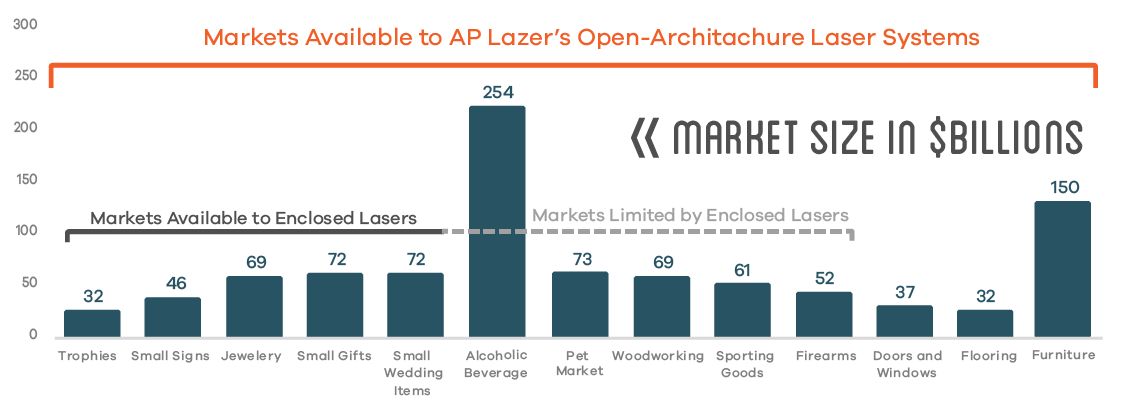

With our open architecture design, you can bring laser engraving and laser cutting into untouched markets. Imagine what it will be like when people find out about the capabilities of your machine! Take a look at the chart below. While a smaller machine (including the traditional “boxed-up” style) has access to 290 billion in market revenue, a larger AP Lazer system can tap into a whopping $1,018 billion dollars in market revenue.

9. All Machines Come With Training

Purchase any one of our machines for one-on-one virtual training from one of our technical support staff. You’ll get 8 hours of training with our larger machines, and 4 hours of training with our smaller machines. These are the same technicians that will be providing you 24/7/365 phone support after your purchase. Did we mention that the support is for the lifetime of your machine?

It’s worth mentioning that in addition to 24/7/365 technical support, ALL of our AP Lazer machines come with access to AP Lazer University, an engaged Facebook User Group, and a 3/2/1 warranty that can’t be beat.

10. Explore Other Possibilities with Our Galvo Fiber Laser Machines

Our 30 and 50-watt fiber markers are designed to be THE high-speed marking solution for small to medium-sized metal and plastic products. What does this mean for your business? High speed, high-precision markings. We’re all about versatility, so this machine comes with TWO power options. Choose from our 30w model or our 50w model, depending on your needs. Both options require 100v of power. The APG30C and APG50C come with a laptop, a rotary tool, technical phone support (M-F, 8-5 PM EST), and 4 hours of virtual training. All machines are covered by our 3-year machine and parts warranty. You can download the spec sheet here.

What makes AP Lazer different?

AP Lazer machines are the most versatile laser machines on the market. That is because we have a patented, open-architecture design in which the entire bottom can be open underneath the laser machine – allowing you to engrave/cut any sized item!

Have questions about any of our machines? Use our online form to contact us or give us a call at 800-585-8617.

0 Comments